ONO EXPONENTIAL FARMING:

THE FUTURE OF AGRI-TECH AHEAD OF US.

ONO EXPONENTIAL FARMING is controlled by robotic technology, artificial intelligence and machine learning algorithms.

There is no space for human error.

This is a complete integrated system, which doesn’t resemble a domotic system approach so much as a real robotic platform. ONO/EF’s level of automation is 100%. Machine learning algorithms and AI operate the farm.

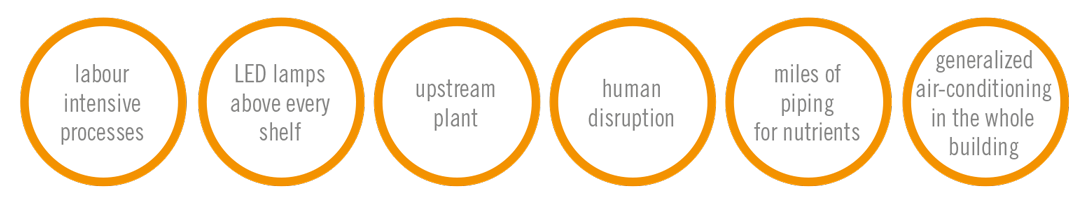

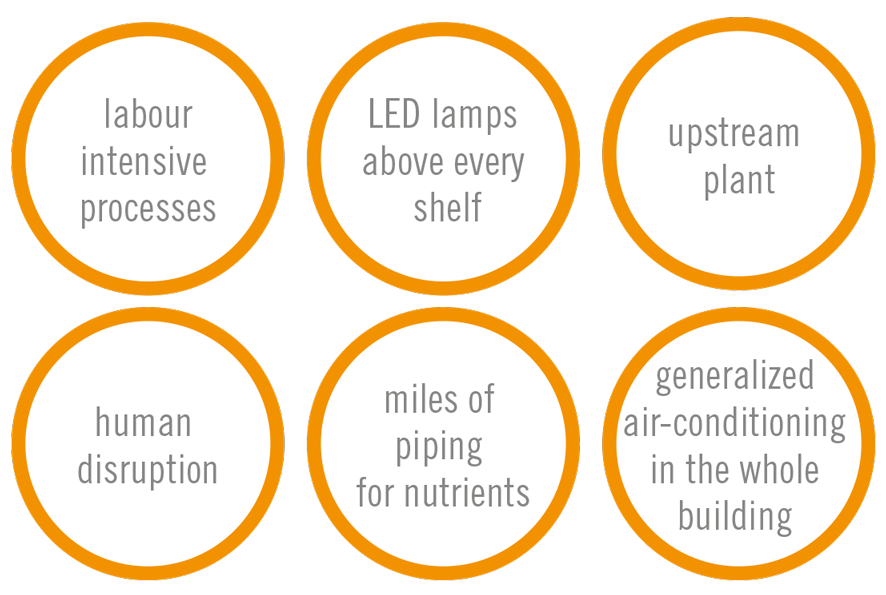

Vertical Farming is a recent industry with a very fragmented competitive framework, which features both vertical growers and providers of Vertical Farming technological systems. The Vertical Farming tech providers currently on the marketplace offer only part of the vertical farming system and almost none of them are able to supply their customers with a complete integrated solution.

ONO/EF fills the gap and goes beyond.

THE AUTOMATION TECHNOLOGY CURRENT LEVELS.

HERE WE ARE.

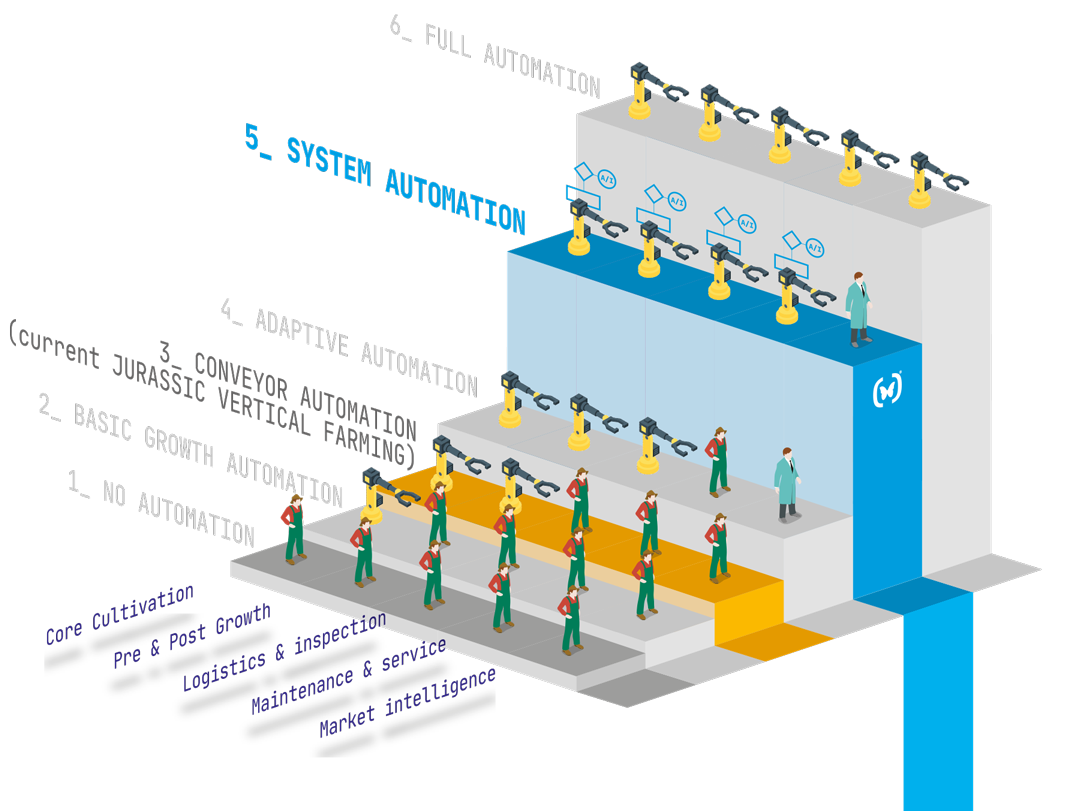

Level 1_ NO AUTOMATION

All processes within the vertical farm are managed by human decision making and labour.

Level 2_ BASIC GROWTH AUTOMATION

All subsystems that mantain the life-cycle of the plant (i.e. lighting on/off, nutrient PH control, air temp, and humidity control) can mantain cycles and set points without human input.

Level 3_ CONVEYOR AUTOMATION (current Jurassic vertical farming)

The beginning and end phases of the crop cycle (i.e. seeding, germinating, harvesting, packaging) are automated using non-intelligent machines, much like traditional manufacturing.

Level 4_ ADAPTIVE AUTOMATION

There is no human interaction with the plants, which are moved, fed, monitored and inspected by machines and computers that can adaptively respond to plants needs.

Level 5_ SYSTEM AUTOMATION (ONO Exponential Farming)

The only human intervention is in defining the outputs of the self-sufficient system; all farm operations are automated, including required input refills, servicing and maintenance operations.

Level 6_ FULL AUTOMATION

The only humans involved are customers; the farm responds automatically to the demand of the market and coordinates logistics and delivery without human decision-making and labor.

ONO/EF is ahead of the curve in every way:

productivity, sustainability, safety, automation and technology, social impact, scalability.

The agricultural revolution is indoors, the future is vertical. We’ve resolved the causes of non-sustainability of the existing concepts and gone much further.

In the ONO/EF farms plant growth is constant, independently of the seasons outside, respecting the natural life cycle of the plant and with environmental conditions that are always optimal. Not even nature can guarantee such perfect conditions. We harvest all year round. Up to 85 tons of lettuce can be harvested per year with just one ONO module.

_AUTOMATION

_OPTIMIZATION OF GROWING PHASES

_LED LIGHTING SYSTEM TECHNOLOGY

• Up to 30% savings on costs of lighting and feeding equipment compared with existing vertical farms.

• Up to 70% reduction in electricity used for growing the crops.

• 80% reduction in labor costs for running the farm.

• Optimization of the desired quality characteristics of the crops due to the possibility to stimulate growth using different climate and light conditions.

_OPTIMIZATION OF GROWING PHASES

_LED LIGHTING SYSTEM TECHNOLOGY

• Up to 70% reduction in electricity used for growing the crops.

• 80% reduction in labor costs for running the farm.

• Optimization of the desired quality characteristics of the crops due to the possibility to stimulate growth using different climate and light conditions.

ONO/EF is not just a farm, but an A/I driven ecosystem.

A proprietary algorithm regulates the vital functions, the crop cycles, the test routines and every operational aspect of the farm.

The algorithm is constantly being developed and updated with A/I self-learning. A global knowledge database collects and shares local experiences with all the ONO/EF farms around the world.

The A/I of the ONO/EF system can anticipate the growth trend of the crops and suggest or autonomously implement any corrective action necessary.

The computer vision system detects the crop’s growth state while the picture matching algorithms reconstruct the entire cultivated area to identify any variations in leaf development on the expected parameters.

WE DON’T FORECAST THE WEATHER.

WE CREATE IT.

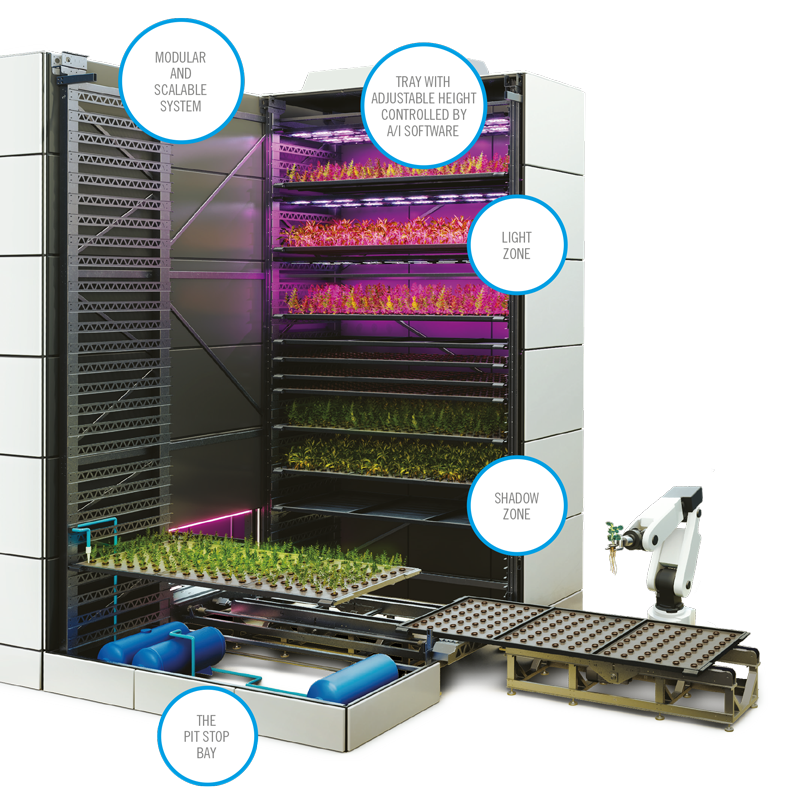

ONO/EF launches the concept of CLIMATEPERIOD™, which allows the plants to develop their perfume and taste molecules and desired nutritional properties in a natural way, in an indoor environment.

Every ONO module has ONOCLIMA™ a dynamic weather generation system, which allows every single module of the farm to independently regulate temperature, humidity, CO2, ionization levels and air purification, differentiating the climate in every single rack of the farm with automated technology. A laminar flow, constructed with a patented system of internal channeling, ensures the constant circulation and recycling of air around the crops, like a continuous breeze.

The internal environment of every rack is totally isolated from the others and from the outside. The farm is pressurized to block the entry of bacteria and pathogens in a natural way.

WE FEEL THE MAGIC OF THE GROWTH.

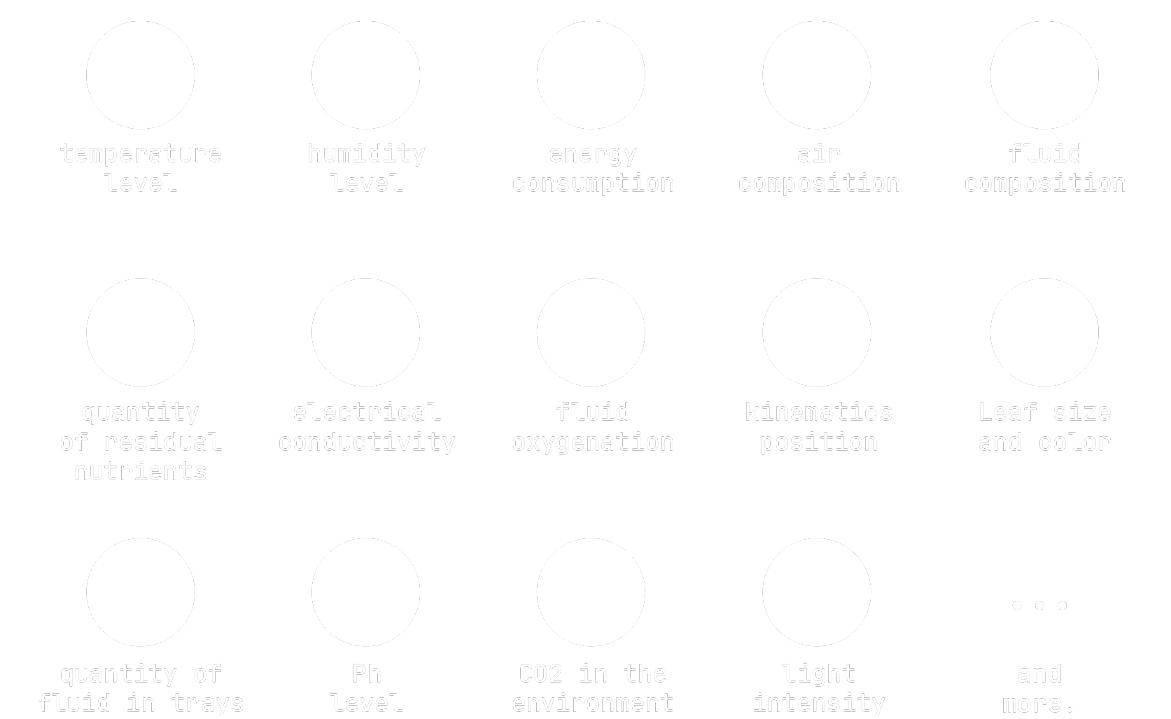

Human intervention is not necessary in our modules. The state of growth and the working of the farm are controlled by a complex system of sensors positioned all over the structure.

The system is made up of environmental sensors analysing chemical/physical and visual properties as well as properties of electrical variable and position, ultrasonic sensors, flow switches, pressure switches, encoders and spectrometers.

The data collected feed the neural networks of the proprietary A/I algorithms.

THE RIGHT LIGHT, THE RIGHT LIFE.

The lighting system is fundamental for the best growth results, and ONO/EF has optimized its performance.

This system is controlled by microcontrollers with edge computing that self-regulate the power of the photon emission. The modularity of the lighting in the ONO/EF system enables the optimization of LED assembly according to actual crop needs.

ONO/EF saves more than 70% in electricity costs compared with current vertical farms with its proprietary system of automatized handling and its research into lighting systems which led to the concept of the Dynamic photo-period™, another unique feature of the ONO/EF system.

Big data sharing.

The ONO/EF module is an authentic global laboratory that allows industrial-scale production. It provides the roots for a farm that can grow, module by module, without interrupting its activity. It can be part of an ecosystem of information exchange for the exponential development of agronomic experimentation.

The grower can interact with the system in complete safety, testing different production methods in the different trays, and can share growth data on the cloud to cooperate with other growers and scientists all over the world in the definition of new growth protocols.

Each tray is considered a single entity with its own ID. Each ID is associated with a standard or modified growth cycle according to cycles that vary by nutrition type, DYNAMIC PHOTO PERIOD™ or CLIMAPERIOD™.

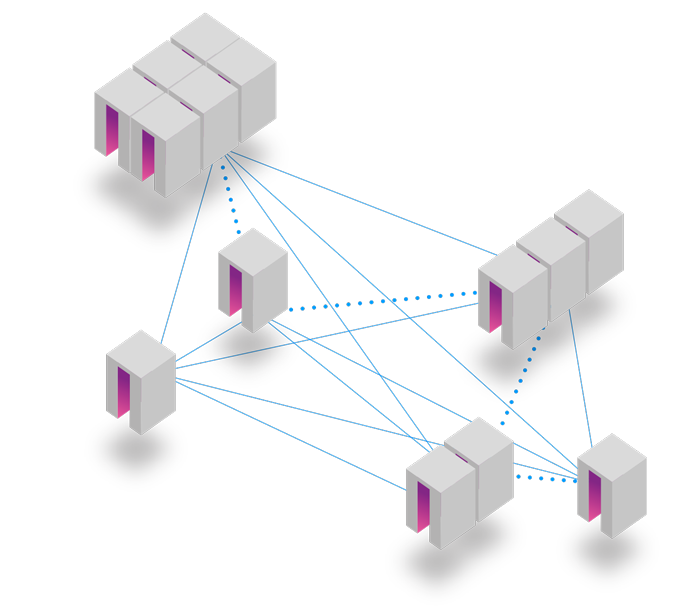

Networking.

All the results processed by the data collection system can be shared, thus generating an open information system of strategic importance for all users of the ONO/EF system.

Remote recovering & shared knownledge.

All ONO Exponential Farms are connected to each other. Remote maintenance services can be carried out by the Farm ZERO technicians or on location via augmented reality.

ONO EXPONENTIAL FARMING:

THE FUTURE OF AGRI-TECH AHEAD OF US.

ONO EXPONENTIAL FARMING is controlled by robotics, artificial intelligence and machine learning algorithms.

There is no space for human error.

This is a complete integrated system, which doesn’t resemble a domotic system approach so much as a real robotic platform. ONO/EF’s level of automation is 100%. Machine learning algorithms and AI operate the farm.

Vertical Farming is a recent industry with a very fragmented competitive framework, which features both vertical growers and providers of Vertical Farming technological systems. The Vertical Farming tech providers currently on the marketplace offer only part of the vertical farming system and almost none of them are able to supply their customers with a complete integrated solution.

ONO/EF fills the gap and goes beyond.

THE AUTOMATION CAPABILITY CURRENT LEVELS.

HERE WE ARE.

Level 1_ NO AUTOMATION

All processes within the vertical farm are managed by human decision making and labour.

Level 2_ BASIC GROWTH AUTOMATION

All subsystems that mantain the life-cycle of the plant (i.e. lighting on/off, nutrient PH control, air temp, and humidity control) can mantain cycles and set points without human input.

Level 3_ CONVEYOR AUTOMATION (current Jurassic vertical farming)

The beginning and end phases of the crop cycle (i.e. seeding, germinating, harvesting, packaging) are automated using non-intelligent machines, much like traditional manufacturing.

Level 4_ ADAPTIVE AUTOMATION

There is no human interaction with the plants, which are moved, fed, monitored and inspected by machines and computers that can adaptively respond to plants needs.

Level 5_ SYSTEM AUTOMATION (ONO Exponential Farming)

The only human intervention is in defining the outputs of the self-sufficient system; all farm operations are automated, including required input refills, servicing and maintenance operations.

Level 6_ FULL AUTOMATION

The only humans involved are customers; the farm responds automatically to the demand of the market and coordinates logistics and delivery without human decision-making and labor.

ONO/EF is ahead of the curve in every way:

productivity, sustainability, safety, automation, social impact, scalability.

The agricultural revolution is indoors, the future is vertical. We’ve resolved the causes of non-sustainability of the existing concepts and gone much further.

In the ONO/EF farms plant growth is constant, independently of the seasons outside, respecting the natural life cycle of the plant and with environmental conditions that are always optimal. Not even nature can guarantee such perfect conditions. We harvest all year round. Up to 85 tons of lettuce can be harvested per year with just one ONO module.

_AUTOMATION

_OPTIMIZATION OF GROWING PHASES

_LED LIGHTING SYSTEM TECHNOLOGY

• Up to 30% savings on costs of lighting and feeding equipment compared with existing vertical farms.

• Up to 70% reduction in electricity used for growing the crops.

• 80% reduction in labor costs for running the farm.

• Optimization of the desired quality characteristics of the crops due to the possibility to stimulate growth using different climate and light conditions.

_OPTIMIZATION OF GROWING PHASES

_LED LIGHTING SYSTEM TECHNOLOGY

• Up to 70% reduction in electricity used for growing the crops.

• 80% reduction in labor costs for running the farm.

• Optimization of the desired quality characteristics of the crops due to the possibility to stimulate growth using different climate and light conditions.

ONO/EF is not just a farm, but an A/I driven ecosystem.

A proprietary algorithm regulates the vital functions, the crop cycles, the test routines and every operational aspect of the farm.

The algorithm is constantly being developed and updated with A/I self-learning. A global knowledge database collects and shares local experiences with all the ONO/EF farms around the world.

The A/I of the ONO/EF system can anticipate the growth trend of the crops and suggest or autonomously implement any corrective action necessary.

The computer vision system detects the crop’s growth state while the picture matching algorithms reconstruct the entire cultivated area to identify any variations in leaf development on the expected parameters.

WE DON’T FORECAST THE WEATHER.

WE CREATE IT.

ONO/EF launches the concept of CLIMATEPERIOD™, which allows the plants to develop their perfume and taste molecules and desired nutritional properties in a natural way, in an indoor environment.

Every ONO module has ONOCLIMA™ a dynamic weather generation system, which allows every single module of the farm to independently regulate temperature, humidity, CO2, ionization levels and air purification, differentiating the climate in every single rack of the farm. A laminar flow, constructed with a patented system of internal channeling, ensures the constant circulation and recycling of air around the crops, like a continuous breeze.

The internal environment of every rack is totally isolated from the others and from the outside. The farm is pressurized to block the entry of bacteria and pathogens in a natural way.

No climate issues.

The unpredictability of the weather and the deterioration of the global climate are no longer a tragic variable; the indoor ONO/EF ecosystem can be constantly controlled and optimized.

Anywhere.

The ONO/EF ecosystem can be installed anywhere in the world, regardless of the typical local weather conditions, in urban, suburban or underground locations.

WE FEEL THE MAGIC OF THE GROWTH.

Human intervention is not necessary in our modules. The state of growth and the working of the farm are controlled by a complex system of sensors positioned all over the structure.

The system is made up of environmental sensors analysing chemical/physical and visual properties as well as properties of electrical variable and position, ultrasonic sensors, flow switches, pressure switches, encoders and spectrometers.

The data collected feed the neural networks of the proprietary A/I algorithms.

THE RIGHT LIGHT, THE RIGHT LIFE.

The lighting system is fundamental for the best growth results, and ONO/EF has optimized its performance.

This system is controlled by microcontrollers with edge computing that self-regulate the power of the photon emission. The modularity of the lighting in the ONO/EF system enables the optimization of LED assembly according to actual crop needs.

ONO/EF saves more than 70% in electricity costs compared with current vertical farms with its proprietary system of automatized handling and its research into lighting systems which led to the concept of the Dynamic photo-period™, another unique feature of the ONO/EF system.

Big data sharing.

The ONO/EF module is an authentic global laboratory that allows industrial-scale production. It provides the roots for a farm that can grow, module by module, without interrupting its activity. It can be part of an ecosystem of information exchange for the exponential development of agronomic experimentation.

The grower can interact with the system in complete safety, testing different production methods in the different trays, and can share growth data on the cloud to cooperate with other growers and scientists all over the world in the definition of new growth protocols.

Each tray is considered a single entity with its own ID. Each ID is associated with a standard or modified growth cycle according to cycles that vary by nutrition type, DYNAMIC PHOTO PERIOD™ or CLIMAPERIOD™.

Networking.

All the results processed by the data collection system can be shared, thus generating an open information system of strategic importance for all users of the ONO/EF system.

Remote recovering & shared knownledge.

All ONO Exponential Farms are connected to each other with innovative technology. Remote maintenance services can be carried out by the Farm ZERO technicians or on location via augmented reality.